Obviously for solving above mentioned problems a kind of binder for the ceramic coating separators with high temperature thermal stability and non swelling property in the electrolytes is needed.

High temperature ceramics coating.

Our ceramic insulation coating reflects and retains heat in order to protect your refractory and metal firing equipment.

Itc coatings provides innovative high temperature ceramic coating for equipment that reaches intense levels of heat such as kilns forges furnaces ovens and more.

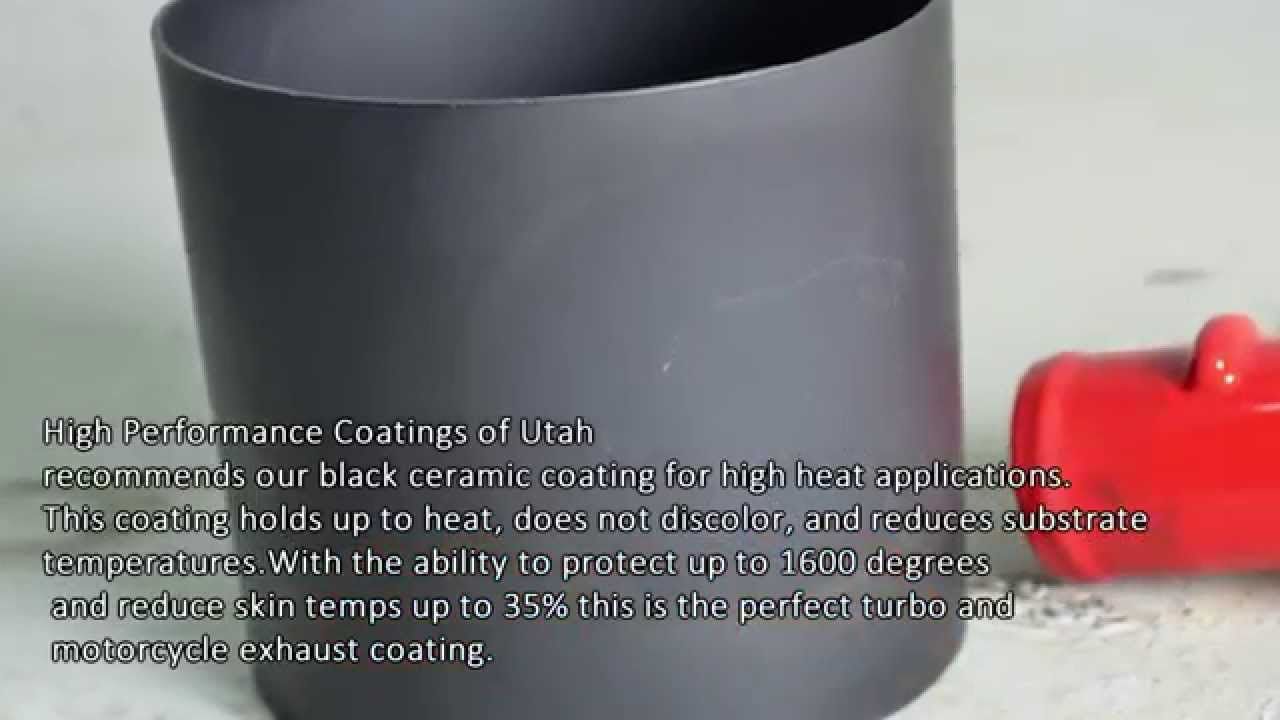

This unique coating is a matte finish silicone ceramic base widely used by the automotive industry on exhaust systems and the aerospace industry for jet engines re entry vehicles and other high temperature applications.

High temperature ceramic coatings are recommended for use on parts that are exposed to extremely high temperatures.

Why use the high temperature ceramic coating process.

Our ceramic coating is highly effective when used on engine exhaust system components including exhaust manifolds exhaust headers cat boxes turbochargers and tailpipes helping to protect sensitive components from the effects.

Our products work well for forge coating and metalworking.

Vht flame proof ceramic coating will extend the life of any surface exposed to extremely high temperatures.

It is ideal for parts exposed to extreme temperatures 2 000 f such as exhaust pipes headers manifolds turbo housings intakes and brackets.

Ceramic coating can be applied over chrome aluminum carbon steel stainless steel or cast iron.

Thirdly more than 20 in weight of such binders were used for preparing ceramic coating separator resulting in high product cost of the separator.

High temperature anti oxidizing corrosion resistant ceramic composite coating for aircraft engine components.

Using the high temperature ceramic coating process there will be a noticeable.

Xiaochao jin xueling fan chunsheng lu tiejun wang advances in oxidation and ablation resistance of high and ultra high temperature ceramics modified or coated carbon carbon composites journal of the european ceramic society 10 1016 j jeurceramsoc 2017 08 013 38 1 1 28 2018.

Innovative coatings that can shield functional surfaces from environmental and temperature impact are essential to increase the life time of devices and reduce the maintenance costs.

Greenshield series high temperature ceramic based water based boiler tube coating with over 25 years of continual development and refinement our greenshield series of ceramic coatings boiler tube coating ensures that wherever corrosion abrasion slagging chemical attack and thermal wear are problems you ll find a proven greenshield product to solve it.

Because of its high temperature capabilities it offers excellent protection when exposed to cyclic high temperature and corrosive salt environments continuing to provide sacrificial properties at temperatures to 1150 f.

Superhydrophobic ceramic coatings with self cleaning properties and stability at high temperatures up to 300 c are eco friendly alternative to aggressive surface cleaning agents.